Steel is indispensable in modern construction due to its strength, versatility, and durability. Selecting the right steel is critical to ensuring your project’s safety, longevity, and cost-effectiveness.

Here’s an in-depth guide on How to choose quality steel for Your Building Projects

How to Choose Quality Steel for Your Building Projects

1. Understand the Different Types of Steel

Steel comes in various types, each suited for specific purposes. Understanding these types helps you make an informed choice:

- Mild Steel: Known for its ductility and weldability, it’s commonly used in structural frameworks.

- Stainless Steel: Resistant to rust and corrosion, making it ideal for coastal regions or areas with high moisture.

- Carbon Steel: High strength and hardness, often used in industrial structures and heavy machinery.

- Alloy Steel: Enhanced with other elements like chromium or nickel to improve strength, durability, and heat resistance.

Pro Tip: Match the steel type to the environmental and structural demands of your project.

2. Check for Certifications and Standards Compliance

Quality steel must meet specific industry standards. Certifications ensure that the steel adheres to safety and performance benchmarks.

Why It Matters: Using uncertified steel could compromise the safety and durability of your structure.

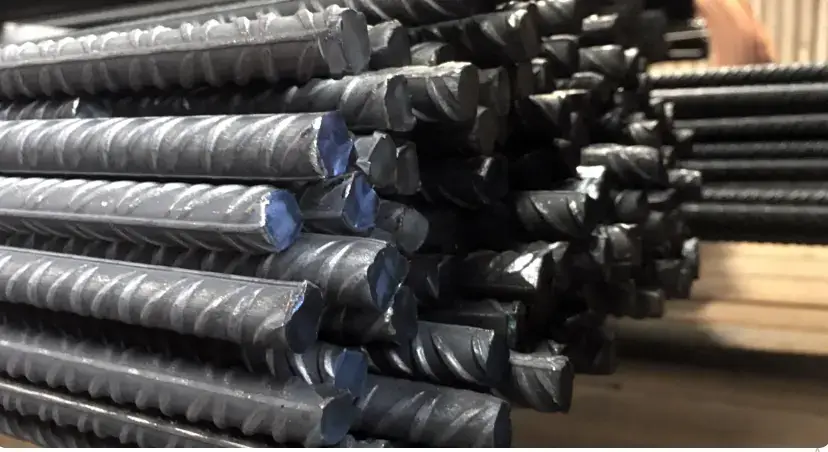

3. Inspect the Physical Quality

Performing a physical inspection is essential to verify the quality of the steel:

- Surface Appearance: Check for rust, cracks, or pitting. Quality steel should have a smooth, defect-free surface.

- Dimensional Accuracy: Ensure the steel’s size and weight match the project specifications.

- Flexibility and Strength: Test samples for durability and elasticity, especially for structures exposed to high stress.

4. Focus on Corrosion Resistance

Corrosion is a major concern in steel structures, particularly in environments prone to moisture or salty air. The right type of steel and proper treatment can mitigate this issue:

- Galvanized Steel: Coated with zinc for excellent rust protection.

- Stainless Steel: Naturally resistant to corrosion due to its chromium content.

- Protective Coatings: Use anti-rust paints or epoxy coatings for additional protection.

5. Evaluate Supplier Reputation

The quality of steel heavily depends on the supplier. Work with manufacturers or suppliers known for delivering high-quality materials.

- Research Reviews: Look for feedback and testimonials from other contractors or builders.

- Check Credentials: Ensure the supplier provides certified steel with clear documentation.

- Customer Support: A reliable supplier should offer assistance in selecting and testing materials.

Pro Tip: Visit the supplier’s facility if possible to inspect their processes and quality control measures.

6. Balance Quality and Budget

Steel costs can vary significantly. While it’s tempting to choose cheaper options, investing in quality steel saves money in the long run by reducing maintenance and repair costs.

- Compare Prices: Get quotes from multiple suppliers to ensure you’re getting a fair deal.

- Consider Bulk Discounts: Purchasing larger quantities often reduces the cost per unit.

7. Understand the Environmental Impact

As sustainability becomes a priority in construction, choosing eco-friendly steel is increasingly important. Look for:

- Recyclable Steel: Many types of steel are recyclable, reducing environmental impact.

- Low-Carbon Steel Options: Opt for suppliers offering materials with reduced carbon footprints.

Why It Matters: Using sustainable materials can boost your project’s eco-credentials.

8. Seek Professional Guidance

If you’re uncertain about the right steel for your project, consult professionals such as:

- Structural Engineers: They can determine the exact specifications based on load-bearing requirements.

- Architects: They ensure the steel fits the design’s aesthetic and functional needs.

Conclusion

Choosing quality steel for your building projects is not just about picking a material—it’s about ensuring the safety, durability, and efficiency of your construction. By understanding the types of steel, verifying certifications, inspecting physical quality, and working with reputable suppliers, you can make informed decisions that benefit your project in the long term.